Established in 1988, IMACRO offers refractory products, magnesium and aluminum sacrificial anodes, magnesium extrusions, strontium metal, specialty alloys and consulting services to the iron, steel, aluminum and other non-ferrous metals and manufacturing industries. This can make you earn about 26$ doing nothing 0.00001420.24.7.4=0.0095424 = 26,81$( 1 BTC = 2801$).

Chemical composition

| Variant | Cast | Di | Weldability | C % | Si % | Mn % | P % | S % | Cr % | Nb % | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Imacro M, 8302 | CC | 1.44 | CEV 1.05max | Min | 0.03 | 0.10 | 0.85 | - | - | 3.75 | 0.040 |

| Pcm 0.32max | Max | 0.06 | 0.40 | 1.15 | 0.025 | 0.035 | 4.40 | 0.080 |

Mechanical Properties

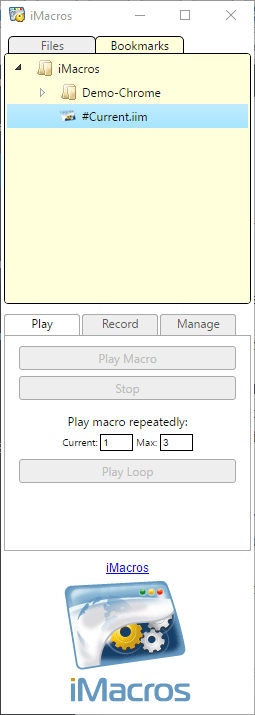

Imacro Download

| Variant | Condition | Format | Dimension [mm] | Yield strength min [MPa] | Tensile strength [MPa] | Elongation A5[%] | Reduction of area Zmin[%] | Hardness | Impact (ISO-V) strengthmin |

|---|---|---|---|---|---|---|---|---|---|

| Rp0.2 * Reh, ** Rel | |||||||||

| Imacro M, 8302 | +AR | Round bar | 25 < 140 | - | - | - | - | < 320 HB | - |

| +QT | Round bar | 25 < 140 | 700 | 800-1000 | 12 | 55 | < 290 HB | -40 °C 35 J (long) | |

Transformation temperatures

| Temperature °C | |

|---|---|

| MS | 398 |

| AC1 | 770 |

| AC3 | 870 |

Other properties (typical values)

| Youngs module (GPa) | Poisson´s ratio (-) | Shear module (GPa) | Density (kg/m3) |

|---|---|---|---|

| 210 | 0.3 | 80 | 7800 |

| Average CTE 20-300°C (µm/m°K) | Specific heat capacity 50/100°C (J/kg°K) | Thermal conductivity Ambient temperature (W/m°K) | Electrical resistivityAmbient temperature (µΩm) |

| 12 | 460 - 480 | 40 - 45 | 0.20 - 0.25 |

Contact us

Would you like to know more about our offers? Don´t hesitate to contact us:

Via e-mail: info@ovako.com

Via telephone: +46 8 622 1300

For more detailed information please visit http://www.ovako.com/en/Contact-Ovako/

Imacros For Chrome Extension

Disclaimer

Imacros Free Download

The information in this document is for illustrative purposes only. The data and examples are only general recommendations and not a warranty or a guarantee. The suitability of a product for a specific application can be confirmed only by Ovako once given the actual conditions.The purchaser of an Ovako product has the responsibility to ascertain and control the applicability of the products before using them. Continuous development may necessitate changes in technical data without notice. This document is only valid for Ovako material. Other material, covering the same international specifications, does not necessarily comply with the properties presented in this document.